MEDICINAL CHEMISTRY AT ITS BEST, Tracks information on drugs on worldwide basis by Dr Anthony Melvin Crasto, Worlddrugtracker helping millions with websites, 6 million hits on google, one lakh connections worldwide, email amcrasto@gmail.com, +91 9323115463 INDIA

Pages

▼

Pages

▼

Saturday, 11 October 2014

QUALITY BY DESIGN (QBD) IN API

Nabriva’s lefamulin, BC 3781 receives FDA fast-track status to treat CABP and ABSSSI

Nabriva’s lefamulin receives FDA fast-track status to treat CABP and ABSSS

Austria-based Nabriva Therapeutics has received qualified infectious disease product (QIDP) and fast-track status designation from the US Food and Drug Administration for its lefamulin (BC 3781).

Austria-based Nabriva Therapeutics has received qualified infectious disease product (QIDP) and fast-track status designation from the US Food and Drug Administration for its lefamulin (BC 3781).

read

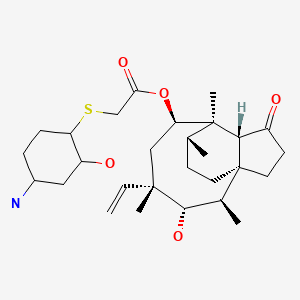

BC-3781

Topical pleuromutilin antibiotic agent

Gram-positive, including MRSA, PHASE 2 COMPLETED,Infection, acute bacterial skin and skin structure (ABSSSI)

Nabriva (Austria), Nabriva Therapeutics AG

BC-3781

cas 1061872-97-6

UNII-61H04Z5F9K

(3aS,4R,5S,6S,8R,9R,9aR,10R)-5-Hydroxy-4,6,9,10-tetramethyl-1-oxo-6-vinyldecahydro-3a,9-propanocyclopenta[8]annulen-8-yl [[(1R,2R,4R)-4-amino-2-hydroxycyclohexyl]sulfanyl]acetate;

14-O-[2-[(1R,2R,4R)-4-Amino-2-hydroxycyclohexylsulfanyl]acetyl]mutilin

BC-3781 is a pleuromutilin antibiotic in early clinical development at Nabriva for the treatment of community acquired pneumonia and for the treatment of patients with acute bacterial skin and skin structure infections (ABSSSI). Pleuromutilin antibiotics interfere with bacterial protein synthesis via a specific interaction with the 23S rRNA of the 50S bacterial ribosome subunit. They have a distinct antibacterial profile and show no cross-resistance with any other class of antibiotics. In 2012, a codevelopment agreement was signed between Forest and Nabriva, but, in 2014, this agreement terminated and Nabriva retained all rights.

The pleuromutilin BC-3781 belongs to the first generation of pleuromutilins to combine excellent oral

bioavailability with substantial activity against Gram-positive pathogens and atypicals as well as some

Gram-negative pathogens. In particular, BC-3781 is highly active against multi-drug resistant (MDR)

pathogens including methicillin resistant Staphylococcus aureus (MRSA), MDR Streptococcus pneumonia

(i.e. macrolide and quinolone resistance), and vancomycin resistant Enterococcus faecium. It is

characterized by excellent in vivo activities (e.g. pneumonia model), outstanding PK/PD parameters,

allowing once a day dosing, and a novel mode of action. BC-3781 is being developed for both oral and IV

administration and is intended for the treatment of serious multi-drug resistant skin & skin structure

infections (CSSI) and moderate to severe pneumonia (CAP, HAP etc).

Pleuromutilins have been known since 1951, but only entered the market in 2007 with the approval of retapamulin for topical use. Until today, there are no pleuromutilins for systemic use approved in human clinical practice.

in 2007 with the approval of retapamulin for topical use. Until today, there are no pleuromutilins for systemic use approved in human clinical practice.

Nabriva is currently working on the development of new compounds is this class. The lead compound, BC-3781, if approved, will be the first pleuromutilin for systemic use in humans.

The compound shows potent in vitro activity against a large collection of staphylococci, streptococci, andE. faecium. When compared to linezolid and vancomycin, the compound shows greater overall potency againstS. aureus [121]. BC-3781 shows improved activity against most bacteria commonly associated with community-acquired respiratory tract infections, the compound is especially potent against S. pneumoniaincluding penicillin resistant strains. It also shows improved activity against H. influenza, M. catarrhalis, M. pneumoniae and C. pneumoniae.

BC-3781 is undergoing Phase I clinical trials for CAP and in March of 2011 has completed a Phase II clinical study comparing it to vancomycin for treatment of aBSSSI [119,120,121,122,123]. Nabriva Therapeutics AG announced that the cooperation with Forest Laboratories to develop the compound had elapsed, and that Nabriva retained all rights in BC-3781. The company informed that the product was Phase III ready and that it was seeking partners to continue further development [203].

Nabriva is also developing BC-7013 for topical use against Gram-positive infections and working on the discovery of new pleuromutilins [119,124].

Dr William Prince, CMO Nabriva Therapeutics commented:

“This is the first patient study with a systemic pleuromutilin. It will be an important proof of concept

for an exciting new class of antibiotics. The phase II study builds on our extensive preclinical and

phase I data which have demonstrated that BC-3781 can achieve therapeutically relevant blood and

tissue levels in man with excellent tolerability when administered by either oral or intravenous

routes.”

“This is the first patient study with a systemic pleuromutilin. It will be an important proof of concept

for an exciting new class of antibiotics. The phase II study builds on our extensive preclinical and

phase I data which have demonstrated that BC-3781 can achieve therapeutically relevant blood and

tissue levels in man with excellent tolerability when administered by either oral or intravenous

routes.”

Dr. David Chiswell, CEO Nabriva Therapeutics commented:

“With a worldwide problem due to antibiotic resistant bacteria, there is a very significant need for

new classes of antibiotics with unique modes of action such as the pleuromutilins. The commercial

prospects for BC-3781 as the leading compound of an exciting new class are excellent, especially as it

has an ideal anti-bacterial spectrum for both skin and respiratory infections and is being developed

with both oral and intravenous formulations”

“With a worldwide problem due to antibiotic resistant bacteria, there is a very significant need for

new classes of antibiotics with unique modes of action such as the pleuromutilins. The commercial

prospects for BC-3781 as the leading compound of an exciting new class are excellent, especially as it

has an ideal anti-bacterial spectrum for both skin and respiratory infections and is being developed

with both oral and intravenous formulations”

BC-3781 is highly active against key pathogens, including MRSA, associated with skin infections and

community and hospital acquired pneumonia and is more potent than Linezolid and vancomycin. The

compound’s novel mode of action ensures that it overcomes resistance mechanisms affecting all

approved classes of antibiotics. BC-378

community and hospital acquired pneumonia and is more potent than Linezolid and vancomycin. The

compound’s novel mode of action ensures that it overcomes resistance mechanisms affecting all

approved classes of antibiotics. BC-378

About Nabriva Therapeutics

Nabriva Therapeutics is a biotechnology company focused on developing a new class of antibiotics for

the treatment of serious infections caused by resistant pathogens. Nabriva’s lead systemic product,

BC-3781, is being developed for the treatment of serious skin infections and bacterial pneumonia

caused by S. aureus, , S. pneumoniae, H. influenza, Mycoplasma, Legionella and other bacteria,

including drug resistant strains such as MRSA and vancomycin resistant E. faecium. In addition,

Nabriva Therapeutics’ topical pleuromutilin product candidate, BC-7013, is in clinical phase I. Nabriva

Therapeutics has a proven track record in world-class medicinal chemistry, clinical expertise, a

seasoned management team and solid IP. Nabriva Therapeutics is located in Vienna, Austria.

Nabriva Therapeutics is a biotechnology company focused on developing a new class of antibiotics for

the treatment of serious infections caused by resistant pathogens. Nabriva’s lead systemic product,

BC-3781, is being developed for the treatment of serious skin infections and bacterial pneumonia

caused by S. aureus, , S. pneumoniae, H. influenza, Mycoplasma, Legionella and other bacteria,

including drug resistant strains such as MRSA and vancomycin resistant E. faecium. In addition,

Nabriva Therapeutics’ topical pleuromutilin product candidate, BC-7013, is in clinical phase I. Nabriva

Therapeutics has a proven track record in world-class medicinal chemistry, clinical expertise, a

seasoned management team and solid IP. Nabriva Therapeutics is located in Vienna, Austria.

For more information on Nabriva please visit http://www.nabriva.com. Nabriva Therapeutics AG

…………………………………………

EP 2390245

……………………………………………..

The trivial name mutilin refers to the IUPAC systematic name (1S, 2R, 3S, 4S, 6R, 7R, 8R, 14R)-3,6-dihydroxy-2,4,7,14-tetramethyl-4-vinyl-tricyclo[5.4.3.01,8]tetradecan-9-one. In the examples, pleuromutilin derivatives are numbered in analogy to the mutilin numbering system described by H. Berner (Berner, H.; Schulz, G.; Schneider H. Tetrahedron 1980, 36, 1807-1811.):

…………………………………………………….

Pleuromutilin, a compound of formula A

is a naturally occurring antibiotic, e.g. produced by the basidomycetes Pleurotus mutilus and P. passeckerianus, see e.g. The Merck Index, 13th edition, item 7617. A number of further pleuromutilins having the principle ring structure of pleuromutilin and being substituted at the hydroxy group have been developed, e.g. as antimicrobials.

From WO 02/04414 Al pleuromutilin derivatives, e.g. 14-O-[(Aminocyclohexan-2-yl (and - 3-yl)-sulfanyl)-acetyl]-mutilins; from WO 07/014409 Al e.g. 14-O-[((Mono- or dialkylamino)-cycloalkylsulfanyl)-acetyl]-mutilins and from WO 07/000004 Al e.g. [((Acyl- hydroxy-amino)-cycloalkylsulfanyl)-acetyl]-mutilins, are known.

14-O-{[(1R, 2R, 4R)-4-Amino-2-hydroxy-cyclohexylsulfanyl]-acetyl}- mutilin hydrochloride

Example 1 – 14-O-{[(1R, 2R, 4R)-4-Amino-2-hydroxy-cyclohexylsulfanyl]-acetyl}- mutilin hydrochloride + (IS, 2S, 4S) diastereomer hydrochloride

Step Al. 14-O-{[(1R, 2R, 4R)-4-tert-Butoxycarbonylamino-2-hydroxy- cyclohexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 4S) diastereomer and 14-O-{[(lR, 2R, 5S)-5-i'eri'-Butoxycarbonylamino-2-hydroxy-cyclohexylsulfanyl]-acetyl}- mutilin + (IS, 2S, 5R) diastereomer and

14-0-{[(lR, 2R, 4S)-4-tert-Butoxycarbonylamino-2-hydroxy-cyclohexylsuIfanyl]-acetyl}- mutilin + (IS, 2S, 4R) diastereomer

To a solution of 3,4-epoxycyclohexyl-carbamic acid tert-butyl ester (Gomez-Sanchez, E.; Marco-Contelles J. Tetrahedron 2005, 61, 1207-1219.) (4.27g, 20mmol) and pleuromutilin thiol (Nagarajan, R. Eli Lilly and Company 1978, US4, 130,709) (7.10 g, 18 mmol) in 200 ml of tetrahydrofuran was added aluminum oxide (40 g, Brockmann activity I, neutral) and the resulting mixture was stirred for 40 hours at room temperature. The suspension was filtered and concentrated under reduced pressure. The residue was subjected to chromatography (silica, cyclohcxane / ethyl acetate = 1/1) to yield 14-O-{[(1R, 2R, 4R)-4-ler(- butoxycarbonylamino-2-hydroxy-cyclohcxylsulfanyl]-acctyl}-mutilin + (IS, 2S, 4S) diastereomer (a) (Rf = 0.38, 1.34g, 12%) as well as a mixture of 14-O-{[(1R, 2R, 5S)-5-tert- butoxycarbonylumino-2-hy(lroxy-cyclohcxylsulfnnyl]-ncctyl}-niυtilin + (I S, 2S, 5R) diastereomer and 14-O-{[(1R, 2R, 4S)-4-tert-butoxycarbonylamino-2-hydroxy- cyclυhexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 4R) diastereomer (b) (Rf = 0.26, 2.81 g, 25%) as colorless amorphous foams. (a): 1H NMR (400MHz, DMSOd6, δ, ppm, inter alia): 6.74 (d, IH, NH, J = 7Hz), 6.13 (dd, IH, 19-H, J – I lHz and 18Hz), 5.54 (d, IH, 14-H, J = 8Hz), 5.05 (m, 2H, 20-H), 4.90 (d, IH, 2′-OH, J = 5Hz), 4.48 (d, IH, 11-OH, J = 6Hz), 3.55 – 3.20 (m, 6H, 1 ‘-H, 2‘-H, 4′-H, 11-H, 22-H), 2.40 (bs, IH, 4-H), 1.36 (s, 3H, 15-CH3), 1.35 (s, 9H, tert-butyl), 1.06 (s, 3H, 18-CH3), 0.81 (d, 3H, 17-CH3, J = 7Hz), 0.62 (d, 3H, 16-CH3, J = 7Hz). MS-ESI (m/z): 630 (MNa+), 1237 (2MNa+).

(b): 1H NMR (400MHz, DMSO-de, δ, ppm, inter alia): 6.70 (d, IH, NH, J = 7Hz), 6.12 (dd, IH, 19-H, J = HHz and 18Hz), 5.34 (d, IH, 14-H, J = 8Hz), 5.05 (m, 2H, 20-H), 4.82, 4.78 (d, IH, 2′-OH, J = 4Hz), 4.48 (d, IH, 11-OH, J = 6Hz), 3.55 – 3.20 (m, 5H, 2′-H, 475′-H, 11- H, 22-H), 2.97 (m, IH, 1 ‘-H), 2.40 (bs, IH, 4-H), 1.35 (s, 12H, 15-CH3, tert-butyl), 1.05 (s, 3H, 18-CH3), 0.82 (d, 3H, 17-CH3, J = 7Hz), 0.62 (d, 3H, 16-CH3, J = 7Hz). MS-ESI (m/z): 630 (MNa+), 1237 (2MNa+).

or Step A2. 14-O-{[(1R, 2R, 4R)-4-tert-Butoxycarbonylamino-2-liydroxy- cyclohexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 4S) diastereomer and

14-O-{[(1R, 2R, 5S)-5-tert-Butoxycarbonylamino-2-hydroxy-cyclohexylsulfanyl]-acetyl}- mutilin + (IS, 2S, 5R) diastereomer and

14-O-{[(1R, 2R, 4S)-4-rerf-Butoxycarbonylamino-2-hydroxy-cyclohexylsulfanyl]-acetyl}- mutilin + (IS, 2S, 4R) diastereomer

To a solution of 3,4-epoxycyclohexyl-carbamic acid tert-butyl ester (10 g, 47 mmol) and pleuromutilin thiol (16.6 g, 42 mmol) in 200 ml of methanol and 20 ml of dioxane was added 2N NaOH (21 ml, 42 mmol) and the resulting mixture was stirred for 16 hours at room temperature. After completion of the reaction the pH was set to 7 with diluted HCl and the reaction mixture was concentrated under reduced pressure. The residue was diluted with water and brine and extracted three times with ethyl acetate. The organic layers were dried over sodium sulfate and filtered. The filtrate was concentrated under reduced pressure and after chromatography (silica, cyclohexane / ethyl acetate = 1/1) 14-O-{[(1R, 2R, 4R) A-tert- butoxycarbonylamino-2-hydroxy-cyclohexylsulfanyl] -acetyl }-mutilin + (IS, 2S, 4S) diastereomer (Rf = 0.40, 3.1g, 12% yield) as well as a mixture of 14-O-{[(1R, 2R, 5S)-5-tert- butoxycarbonylamino-2-hydroxy-cyclohexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 5R) diastereomer and 14-O-{[(1R, 2R, 4S)-4-tert-butoxycarbonylamino-2-hydroxy- cyclohexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 4R) diastereomer (Rf = 0.25, 6.35 g, 25%) were obtained as colorless amorphous foams. or Step A3. 14-O-{[(1R, 2R, 4R)-4-tert-Butoxycarbonylamino-2-hydroxy- cyclohexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 4S) diastereomer and 14-O-{ [(1R, 2R, 5S)-5-tert-Butoxycarbonylamino-2-hydroxy-cyclohexylsulfanyl]-acetyl}- mutilin + (IS, 2S, 5R) diastereomer

To a solution of Pleuromutilin thiol (9.25 g, 23.5 mmol) in 100 ml of acetonitrile (dried over 4A molecular sieve) was added l,5-diazabicyclo[4.3.0]non-5-ene (DBN, 2.9 μl, 23.5 mmol) and after 1 hour of stirring at room temperature under argon atmosphere the mixture was ^ charged with syn-3,4-epoxycyclohexyl-carbamic acid tert-butyl ester (4.17 g, 19.5 mmol) and stirred for further 16 hours at room temperature. The reaction mixture was concentrated under reduced pressure. The residue was charged with water and brine and extracted three times with dichloromethane. The organic layers were dried over sodium sulphate and filtered. The filtrate was concentrated under reduced pressure and subjected to chromatography (silica, cyclohexane / ethyl acetate = 1/1) to yield 14-O-{[(1R, 2R, 4R)-4-teAY-butoxycarbonylamino- 2-hydroxy-cyclohexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 4S) diastereomer (Rf = 0.38, 5.07g, 43%) as well as 14-O-{[(1R, 2R, 5S)-5-tert-butoxycarbonylamino-2-hydroxy- cyclohexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 5R) diastereomer (Rf = 0.25, 2.95 g, 16.5%) as colorless amorphous foams.

Step B. 14-O-{[(1R, 2R, 4R)-4-Amino-2-hydroxy-cyclohexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 4S) diastereomer

To a solution of 14-O-{[(1R, 2R, 4R)-4-teΛ-t-butoxycarbonylamino-2-hydroxy- cyclohexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 4S) diastereomer (1.34 g, 2.20 mmol) in 75 ml of dichloromethane was added trifiuoroacetic acid (4 ml) at 4°C and stirred for 5 hours at room temperature. The reaction mixture was diluted with dichloromethane and cautiously poured into a saturated NaHCO3 solution. The phases were separated and the aqueous layer was washed two times with dichloromethane. The combined organic layers are dried over sodium sulfate and filtered. After chromatography (silica, ethyl acetate/methanol/35% ammonia solution = 50/50/1) 14-O-{[(1R, 2R, 4R)-4-amino-2-hydroxy-cyclohexylsulfanyl]- acetyl}-mutilin + (IS, 2S, 4S) diastereomer (745 mg, 67% yield) was obtained as colorless amorphous foam.

1H NMR (400MHz, DMSO-de, δ, ppm, inter alia): 6.14 (dd, IH, 19-H, J = 1 IHz and 18Hz), 5.54 (d, IH, 14-H, J = 8Hz), 5.05 (m, 2H, 20-H), 4.50 (d, IH, 11-OH, J = 6Hz), 3.50 – 3.20 (m, 5H, 2′-H, 4′-H, H-H, 22-H), 2.55 (m, IH, l ‘-H), 2.40 (bs, IH, 4-H), 1.35 (s, 3H, 15- CH3), 1.06 (s, 3H, 18-CH3), 0.82 (d, 3H, 17-CH3, J = 7Hz), 0.62 (d, 3H, 16-CH3, J = 7Hz). MS-ESI (m/z): 508 (MH+), 530 (MNa+), 1015 (2MH+), 1037 (2MNa+).

Step C. 14-O-{[(1R, 2R, 4R)-4-Amino-2-hydroxy-cyclohexylsulfanyI]-acetyl}- mutilin hydrochloride + (IS, 2S, 4S) diastereomer hydrochloride

A solution of 14-O-{[(1R, 2R, 4R)-4-amino-2-hydroxy-cyclphexylsulfanyl] -acetyl }-mutilin + (IS, 2S, 4S) diastereomer (325 mg, 0.64 mmol) in 20 ml of dioxane was treated with IN HCl (0.64ml, 0.64 mmol). After stirring at room temperature for 30 minutes the solution was lyophilized to obtain 14-O-{[(1R, 2R, 4R)-4-amino-2-hydroxy-cyclohexylsulfanyl] -acetyl }- mutilin hydrochloride + (IS, 2S, 4S) diastereomer hydrochloride (quantitative yield) as colorless amorphous solid.

1H NMR (500MHz, DMSO-Cl6, δ, ppm, inter alia): 7.6 (bs, 3H, NH3 +), 6.14 (dd, IH, 19-H, J = 1 IHz and 18Hz), 5.55 (d, IH, 14-H, J = 8Hz), 5.05 (m, 2H, 20-H), 4.52 (d, IH, H-OH, J = 6Hz), 3.50 – 3.20 (m, 4H, 2′-H, H-H, 22-H), 3.03 (m, IH, 4′-H), 2.53 (m, IH, 1 ‘-H), 2.40 (bs, IH, 4-H), 1.37 (s, 3H, 15-CH3), 1.06 (s, 3H, 18-CH3), 0.82 (d, 3H, 17-CH3, J = 7Hz), 0.62 (d, 3H, 16-CH3, J = 7Hz). MS-ESI (m/z): 508 (MH+), 530 (MNa+), 1015 (2MH+), 1037 (2MNa+), 542 (MCl“).

Example IA – 14-O-{[(1S, 2S, 4S)-4-Amino-2-hydroxy-cyclohexylsulfanyl]-acetyl}- mutilin and 14-O-{[(1R, 2R, 4R)-4-Amino-2-hydroxy-cyclohexylsuIfanyl]-acetyl}-mutilin

The mixture of 14-O-{[(1R, 2R, 4R)-4-Amino-2-hydroxy-cyclohexylsulfanyl]-acetyl}-mutilin + (IS, 2S, 4S) diastereomer (12 g, 23.6 mmol) from Example 1 Step B was separated on a cbiral column (250 x 20 mm CHIRALCEL OD-H, n-heptane / ethanol / diethylamine = 80/20/0.1) to yield 14-O-{[(1S*, 2S*, 4S*)-4-amino-2-hydroxy-cyclohexylsulfanyl]-acetyl}- mutilin (a) (early eluting compound, 4.76 g, 37% yield, uncorrected) and 14-O-{[(1R*, 2R*, 4R*)-4-amino-2-hydroxy-cyclohexylsulfanyl]-acetyl}-mutilin (b) (late eluting compound, 3.63 g, 30% yield, uncorrected) as colorless amorphous foams.

(a): 1H NMR (400MHz, DMSO-(I6, δ, ppm, inter alia): 6.13 (dd, IH, 19-H, J = 1 IHz and 18Hz), 5.54 (d, IH, 14-H, J = 8Hz), 5.05 (m, 2H, 20-H), 4.50 (d, IH, H-OH, J = 6Hz), 3.50 – 3.20 (m, 5H, 2′-H, 4′-H, H-H, 22-H), 2.55 (m, IH, l ‘-H), 2.40 (bs, IH, 4-H), 1.35 (s, 3H, 15- CH3), 1.05 (s, 3H, 18-CH3), 0.82 (d, 3H, 17-CH3, J = 7Hz), 0.62 (d, 3H, 16-CH3, J = 7Hz). MS-ESI (m/z): 508 (MH+), 530 (MNa+), 1015 (2MH+), 1037 (2MNa+), 506 (M-H) “, 542 (MCl“).

(b): 1H NMR (400MHz, DMSO-d6> δ, ppm, inter alia): 6.13 (dd, IH, 19-H, J = 1 IHz and 18Hz), 5.54 (d, IH, 14-H, J = 8Hz), 5.05 (m, 2H, 20-H), 4.50 (d, IH, H-OH, J = 6Hz), 3.50 – 3.20 (m, 5H, 2′-H, 4′-H, 11-H, 22-H), 2.55 (m, IH, 1 ‘-H), 2.40 (bs, IH, 4-H), 1.35 (s, 3H, 15- CH3), 1.05 (s, 3H, 18-CH3), 0.82 (d, 3H, 17-CH3, J = 7Hz), 0.62 (d, 3H, 16-CH3, J = 7Hz). MS-ESI (m/z): 508 (MH+), 530 (MNa+), 1015 (2MH+), 1037 (2MNa+), 506 (M-H) “, 542 (MCl“).

…………………………………………………….

WO 2011146954

The present invention relates to crystalline 14-0-{[(4-amino-2-hydroxy-cyclohexyl)- sulfanyl] -acetyl }-mutilin, new processes for its preparation and crystalline salts thereof.

Pleuromutilin, a compound of formula

Pleuromutilin

is a naturally occurring antibiotic, e.g. produced by the basidiomycetes Pleurotus mutilus and P. passeckerianus, see e.g. The Merck Index, 12th edition, item 7694.

A number of further pleuromutilins having the principle ring structure of pleuromutilin and being substituted at the primary hydroxy group have been developed, e.g. as antimicrobials. Due to their pronounced antimicrobial activity, a group of pleuromutilin derivatives, amino- hydroxy-substituted cyclohexylsulfanylacetylmutilins, as disclosed in WO 2008/113089, have been found to be of particular interest. As described in WO2008/11089 14-0-{[(4- Amino-2-hydroxy-cyclohexyl)-sulfanyl] -acetyl }-mutilins are particularly useful compounds because they demonstrate activity against Gram-positive and Gram-negative pathogens e.g. associated with respiratory tract and skin and skin structure infections. For the production of substantially pure isomers/diastereomers of this group of compounds, there is a need for a production process which is convenient for use on an industrial scale and which also avoids the use of costly starting materials, environmentally hazardous reagents and solvents or time consuming and laborious purification steps. The production process described in WO 2008/113089 involves chromatographic purification of the compounds prepared according to individual synthesis steps and the final diastereomers are separated by chiral HPLC chromatography which cannot be used on industrial scale. Surprisingly, crystalline intermediates have been found which on the one hand have unexpected chemical purification potential which is important for the production processes for pure amino-hydroxy-substituted cyclohexylsulfanylacetylmutilins avoiding

chromatographic purification and separation steps.

It has to be pointed out that 14-0-{[(4-amino-2-hydroxy-cyclohexyl)-sulfanyl]-acetyl}- mutilins are potential new drug substances for the human market with regulatory

requirements defined in the corresponding ICH guidelines (International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use). The ICH guideline on impurities in new drug substances (Q3 A(R2)) includes the following thresholds:

As can be seen from the ICH thresholds above it is desirable to have all individual unknown impurities below 0.10% area and the structure elucidated impurities below 0.15%, respectively. Processes provided according to the present invention enable to produce APIs (Active Pharmaceutical Ingredients) within the desired specifications and fulfilling ICH requirements.

On the other hand, even more surprisingly, the crystalline intermediates yields to significant chiral enrichment which has a huge benefit in the production of the pure stereoisomers starting from cheaper racemic materials or less chirally pure starting materials. The described processes do not involve any chromatographic purification neither normal nor chiral phase in contrast to the synthetic procedures described in WO2008/113089 wherein is disclosed e.g. in Example 1, Step B that 14-0-{[(4-amino-2-hydroxy-cyclohexyl)-sulfanyl]- acetyl}-mutilins was isolated in the form of diastereomeric mixtures as colorless amorphous foams after normal phase chromatography. The chiral pure diastereomers are described to have been received in WO2008/113089, e.g. in Example 1 A after subjecting the mixture to chiral chromatography whereafter the separated pure diastereomers were isolated in the form of colorless amorphous foams.

Chiral chromatography, however is not a technology which can be applied on industrial large scale, and moreover no crystalline salts of 14-0-{[(4-amino-2-hydroxy-cyclohexyl)- sulfanyl]-acetyl}-mutilins were obtained according to WO2008/113089. In contrast to that, according to the present invention crystalline pharmaceutical acceptable salts of 14-0-{[(4-amino-2-hydroxy-cyclohexyl)-sulfanyl]-acetyl}-mutilins having surprising and superior properties over the amorphic prior art salts disclosed in

WO2008/113089 have been found; e.g. surprisingly the chemical stability of the crystalline salts of the present invention is improved over the amorphic salt forms; and also and in addition the crystalline salts of the present invention show a surprising low hygroscopicity.

Processes for the preparation of such crystalline salts wherein the salts may be obtained in a single stereoisomeric form from 14-0-{[(4-amino-2-hydroxy-cyclohexyl)-sulfanyl]-acetyl}- mutilins and processes for the preparation of stereoisomerically pure 14-0-{[(4-amino-2- hydroxy-cyclohexyl)-sulfanyl]-acetyl}-mutilins in crystalline form as a basis for the crystalline salts have also been found.

In one aspect the present invention provides a process for the preparation of a compound of formula I

in the form of a single stereoisomer in crystalline form, comprising

deprotecting the amine group

either in a compound of formula Ila

in a mixture of a compound of formula Ila with a compound of formula lib

wherein R is an amine protecting group, and isolating a compound of formula I obtained in the form of a single diastereomer in crystalline form either directly from the reaction mixture or via recrystallization in organic solvent.

In another aspect the present invention provides a compound of formula I as defined above in the form of a single stereoisomer in crystalline form.

Compounds of formula Ila are new and also form part of the present invention.

In another aspect the present invention provides a compound of formula Ha.

In a compound of formula I, or Ha, respectively, the carbon atoms of the cyclohexyl ring to which the hydroxy group, the amine group and the sulfanyl-acetyl-mutilin group are attached are all in the R configuration and thus a compound of formula I, or Ila represents an optionally amine protected 14-0-{[(l ?,2i?,4 ?)-4-amino-2-hydroxy-cyclohexylsulfanyl]- acetyl}-mutilin. In contrast to that, in a compound of formula lb

or lib the carbon atoms of the cyclohexyl ring to which the hydroxy group, the amine group and the sulfanyl-acetyl-mutilin group are attached are all in the S configuration and thus a compound of formula lib represents an optionally amino protected 14-0-{[(lS,2S,4S)-4-Amino-2-hydroxy- cyclohexylsulfanyl] -acetyl } -mutilin. An amine protecting group includes protecting groups known to a skilled person and which are removable under acidic, basic, hydrogenating, oxidative or reductive methods, e.g. by hydrogenolysis, treatment with an acid, a base, a hydride, a sulfide. Appropriate amine protecting groups e.g. are described in T. W. Greene, P. G. M. Wuts, Protective Groups in Organic Synthesis, Wiley-Interscience, 4th edition, 2007, particularly p. 696-868.

Example 1

tert-Butyl [(lR3Ri4R)-3-hydroxy-4-mercapto-cyclohexyl]-carbamate

3.94 Kg of {(li?,2J?,4i?)-4-[(tert-Butoxycarbonyl)-amino]-2-hydroxy-cyclohexyl}-benzene- carbothioate and 37 L of CH2C12 were charged to a vessel and the mixture obtained was stirred at 15-25°C. 0.39 Kg of 1,4-dithio-DL-threitol (10% wt) was added to the mixture and rinsed through with 2 L of CH2C12. To the mixture obtained 0.84 Kg of hydrazine monohydrate was added. The mixture obtained was stirred at 18 to 22°C for 3 h and the reaction was followed by HPLC. Upon completion of the reaction, 39 L of 1 M phosphoric acid solution was added and the mixture obtained was stirred for a further 15-30 min. Two phases formed were separated and the organic phase obtained was washed with 39 L of of 1 M phosphoric acid solution followed by 39 L 1% aqueous NaCl solution. The organic layer obtained was concentrated in vacuo at <40°C, to the concentration residue 20 L of CH2C12 was added and the mixture obtained again was concentrated. To the concentration residue obtained a further 8 L of CH2C12 was added and the mixture obtained was concentrated to dryness.

2.89 Kg of tert-Butyl [(l ?,3/?,4i?)-3-hydroxy-4-mercapto-cyclohexyl]-carbamate in the form of a white solid was obtained.

1H NMR (200 MHz, DMSO-de, ppm) δ 6.79 (d, J=7.8Hz, 1H), 4.99 (d, J=5.8Hz, 1H), 3.34 – 3.24 (m, 1H), 3.14 – 3.04 (m, 1H), 2.37 (d, J=3.8 Hz, 1H), 2.00 -1.89 (m, 1H), 1.87 – 1.82 (m, 1H), 1.73 – 1.67 (m, 1H), 1.47 – 1.04 (m, 12H)

Example 2

22-0-TosylpIeuromutilin

22-O-Tosylpleuromutilin is a known compound from literature. However a preparation procedure is outlined below.

A solution of 13.0 kg of pleuromutilin and 6.57 kg of 4-toluenesulfonyl chloride in 42.1 L of CH2CI2 at 10 to 15 °C was treated with 9.1 L of 5.7 M aqueous NaOH over 20 min, maintaining a temperature < 25 °C. The resulting off-white suspension was heated to reflux for 20 h and the reaction was followed until completion determined by HPLC. Upon reaction completion the mixture obtained was cooled to 20 to 30 °C, diluted with 52 L of CH2C12, stirred at 15 to 25 °C for 10 min, and the layers obtained were separated. The organic phase obtained was washed several times with 52 L of water until a pH of the aqueous layer was adjusted to < 9. The organic layer obtained was concentrated to 4 volumes and

azeotropically dried twice with 52 L of CH2C12. To the solution obtained 52 L of heptane were added dropwise and the solution obtained was concentrated at < 40 °C to

approximately 4 volumes. To the concentrate obtained 52 L of heptane was added and the resulting suspension was stirred at 20 to 25 °C for 2 to 2.5 h, filtered, the filter cake obtained was washed with 39 L of heptane and pulled dry on the filter.

The solid was dried under vacuum at < 40 °C for at least 12 h.

16.9 kg of 22-O-tosylpleuromutilin in the form of a white solid was obtained.

1H NMR (200 MHz, DMSO-d6, ppm, inter alia) δ 7.81 (d, 2H), 7.47 (d, 2H), 6.14 – 6.0 (m, 1H), 5.54 (d, J=7.8Hz, 1H), 5.08 – 4.99 (m, 2H), 4.70 (AB, J=16.2Hz, 2H), 3.41 (d, J=5.2Hz, 1H), 2.41(s, 4H), 1.04(s, 3H), 0.81 (d, 3H), 0.51 (d, 3H)

Example 3

14-0-{[(l/?,2R,4R)-4-ter/-Butoxycarbonylamino-2-hydroxy-cyclohexyI-sulfanyl]-acetyl}- mutilin

4.75 Kg of Pleuromutilin tosylate (Tos-PLEU) and 44.4 L of MTBE were charged into a vessel and to the mixture obtained 0.31 Kg of benzyl-tri-«-butylammonium chloride was added and rinsed through with 2.4 L of MTBE. To the mixture obtained 20 L of IM aqueous NaOH solution and 2.84 Kg of tert-Butyl [(lif,3i?,4^)-3-hydroxy-4-mercapto-cyclohexyl]- carbamate were added and the mixture obtained was stirred at 17 to 23 °C for 3 h. Upon completion of the reaction (determined by HPLC) two layers formed were separated and the lower aqueous layer was removed. The organic phase obtained was washed with 19 L of IM aqueous NaOH solution, twice with 20 L of 0.1 M phosphoric acid, 20 L of 10% aqueous NaHC03 solution and twice with 20 L of water. The organic liquors obtained were concentrated, the concentrate obtained was taken up in 7.46 Kg of 2-propanol, the mixture obtained was concentrated again and dried in vacuo at <40°C. 6.66 Kg of 14-O- { [( 1 -¾,2i?,4i?)-4-/ert-Butoxycarbonylamino-2-hydroxy-cyclohexyl-sulfanyl]-acetyl } -mutilin in the form of a white foam was obtained.

Ή NMR (200 MHz, DMSO-d6, ppm, inter alia) δ 6.78 (d, J=7.8Hz, 1H), 6.22 – 6.08 (m,lH), 5.55 (d, J=7.8Hz, 1H), 5.13 – 5.02 (m, 2H), 4.95 (d, J=5Hz, 1H), 4.52 (d, J=6Hz, 1H), 3.36 (AB, J=15Hz, 2H), 2.40 (s, broad, 1H), 2.15 – 2.0 (m, 3H), 1.9 – 1.8 (m, 1H), 1.35 (s, 9H), 0.81 (d, J=7Hz, 3H), 0.62 (d, J=6.6Hz, 3H)

MS (ESI, g/mol): m/z 653 [M+2Na] +

Example 4

14-0-{[(lR,2R,4R)-4-Amino-2-hydroxy-cyclohexyIsulfanyI]-acetyl}-mutilin, crystalline Form 2

Step A: 14-O-{[(li?.2i?,4i?)-4-Amino-2Thvdroxy-cyclohexylsulfanvn-acetvU-mutilin in crystalline Form 1

6.6 Kg of 14-O-{[(li?,2if,4/?)-4-tert-Butoxycarbonylamino-2-hydroxy-cyclohexyl-sulfanyl]- acetyl}-mutilin and 13.2 L of isopropanol were charged into a vessel and stirred at 20 to 25°C. 11.20 kg of 85% phosphoric acid was added and the mixture obtained was heated to approximately 50°C for at least 16 h. The mixture obtained was analyzed for reaction completion by HPLC. Upon completion of the reaction the mixture was cooled to 20 to 25°C and 52 L of CH2C12 was added. The mixture obtained was cooled to 0 to 5°C and 51 L of 30% aqueous K2CO3 solution was added over 1 h at <25°C. The mixture obtained was warmed to rt, stirred for 30 min and the pH of the aqueous layer was determined. To the mixture obtained a further 15 L of 30% aqueous K2C03solution was added at <25°C, the mixture obtained was stirred at 15°C to 25 °C for 30 min and the two phases obtained were separated. The aqueous phase obtained was extracted with 51 L of CH2CI2 and the combined organic phases were washed with 51 L of purified water. The mixture obtained was concentrated to a volume of 25 L, 33.6 Kg of CH2C12 was added and the mixture obtained was concentrated to 25 L. To the concentrate obtained 33.6 Kg of CH2C12 was added and the mixture obtained was concentrated to 10 L. The concentration residue obtained was cooled to 18 to 22°C and 50 L of di-wopropyl ether was added over a period of 1 h. The slurry obtained was stirred at 15 to 25°C for a minimum of 2 h, filtered and the solid obtained was washed with 10 L of di-wopropyl ether and was dried.

3.79 Kg of 14-0-{[(li?,2i?,4if)-4-Amino-2-hydroxy-cyclohexylsulfanyl]-acetyl}-mutilin in crystalline Form 1 was obtained.

Step B: 14-O-{r(l-R.2i?,4j?)-4-amino-2-hvdroxy-cvclohexylsulfanyl1-acetv -mutilin. in crystalline Form 2

For further purification 14-O-{[(l ?,2 ?,4i?)-4-Amino-2-hydroxy-cyclohexylsulfanyl]- acetyl}-mutilin from Step A and 18.75 L of n-butanol were heated to 88 to 92°C until complete dissolution and stirred for 30 to 60 min. The mixture obtained was allowed to cool to 40 to 45°C over at least 2 h and further stirred at this temperature for 2 h. The mixture obtained was filtered and the precipitate obtained was washed with 3.75 L of «-butanol followed by 3.75 L of MTBE. That purification procedure was repeated and the resultant product was dried in vacuo at <40°C.

3.27 Kg of crystalline 14-0-{[(li?,2if,4i?)-4-amino-2-hydroxy-cyclohexylsulfanyl]-acetyl}- mutilin in crystalline Form 2 was obtained in the form of a white solid.

lH NMR (400 MHz, CDC13, ppm, inter alia) δ 6.51 – 6.44 (m, 1H), 5.78 (d, J=8Hz, 1H), 5.38 – 5.20 (m, 2H), 3.48 – 3.40 (m, 1H), 3.36 (d, J=7Hz, 1H), 3.25 (AB, J=15Hz, 2H), 2.92 – 2.82 (m, 1H), 2.6 – 2.5 (m, 1H), 1.45 (s, 3H), 1.20 (s, 3H), 0.88 (d, J=7Hz, 3 H), 0.73 (d, J=8Hz, 3H)

MS (ESI, g/mol): m/z 508 [M+H] +

Example 5

14-0-{[(lR^/f,4R)-4-Amino-2-hydroxy-cyclohexylsulfanyl]-acetyl}-mutilin, crystalline

To a solution of 900 g of 14-0-{[(li?,2i?,4i?)-4-tert-butoxycarbonylamino-2-hydroxy- cyclohexyl-sulfanyl]-acetyl}-mutilin in 9 L of CH2C12 at 15 to 25°C was added 1.8 L of TFA at 15 to 25°C and the resulting solution was stirred for 2 h. Following reaction completion the reaction mixture was concentrated under vacuum and the concentration residue obtained was azeo-dried with a total of 9 L of CH2C12. The concentrate obtained was dissolved in 4.5 L of CH2C12, the solution obtained cooled to 0 to 5°C and the pH was adjusted to pH 11 with aqueous 3.6 L 2CO3 (2.5M) solution. The biphasic mixture obtained was warmed to 15 to 20°C and stirred for 5 to 10 minutes. The layers obtained were separated, the aqueous phase obtained was extracted with 1.8 L of CH2C12, the organic phases obtained were combined, washed with 2.3 L of H20, dried over Na2S04 and concentrated to dryness under vacuum at <40°C. Crude 14-0- { [( 1 R,2R,4R)-4- Amino-2-hydroxy-cyclohexyl-sulfanyl]-acetyl } -mutilin was obtained. Yield: 744 g

For further purification the following procedure was applied:

To 744 g of crude 14-O-{[(li?,2i?,4i-)-amino-2-hydroxy-cyclohexyl-sulfanyl]-acetyl}- mutilin was added 2.23 L of THF and the resulting suspension was stirred at 15 to 25°C for 60 min. To the mixture obtained 7.44 L of MTBE was added over 15 to 30 min, the suspension obtained was aged for 60 min and filtered under nitrogen. The collected solids were washed with a total of 3 L of MTBE and pulled dry on the filter under nitrogen for 1.5 h.

626 g of 14-0-{[(li?,2i?,4i?)-4-Amino-2-hydroxy-cyclohexyl-sulfanyl]-acetyl}-mutilin in crystalline Form 1 was obtained.

The Ή NMR pattern confirms the structure of 14-O-{[(li?,2i?,4i?)-4-amino-2-hydroxy- cyclohexylsulfanyl] -acetyl} -mutilin. The NMR pattern for 14-O-{[(l ?,2i?,4/?)-4-amino-2- hydroxy-cyclohexylsulfanyl]-acetyl}-mutilin is described in example 4.

…………………………………………………………

REF

119

Nabriva. Pleuromutilins. Available online: http://www.nabriva.com/programs/pleuromutilins/ (accessed on 7 December 2012).

120

120

Forest Laboratories. Our pipeline: Solid, and set for further growth. Available online: http://www.frx.com/research/pipeline.aspx (accessed on 13 April 2013).

121

121

Sader, H.S.; Biedenbach, D.J.; Paukner, S.; Ivezic-Schoenfeld, Z.; Jones, R.N. Antimicrobial activity of the investigational pleuromutilin compound BC-3781 tested against Gram-positive organisms commonly associated with acute bacterial skin and skin structure infections. Antimicrob. Agents Chemother. 2012,56, 1619–1623, doi:10.1128/AAC.05789-11.

122

Sader, H.S.; Paukner, S.; Ivezic-Schoenfeld, Z.; Biedenbach, D.J.; Schmitz, F.J.; Jones, R.N. Antimicrobial activity of the novel pleuromutilin antibiotic BC-3781 against organisms responsible for community-acquired respiratory tract infections (CARTIs). J. Antimicrob. Chemother. 2012, 67, 1170–1175, doi:10.1093/jac/dks001.

Sader, H.S.; Paukner, S.; Ivezic-Schoenfeld, Z.; Biedenbach, D.J.; Schmitz, F.J.; Jones, R.N. Antimicrobial activity of the novel pleuromutilin antibiotic BC-3781 against organisms responsible for community-acquired respiratory tract infections (CARTIs). J. Antimicrob. Chemother. 2012, 67, 1170–1175, doi:10.1093/jac/dks001.

123

Nabriva Therapeutics AG. Study comparing the safety and efficacy of two doses of BC-3781 vs. vancomycin in patients with acute bacterial skin and skin structure infection (ABSSSI). Available online: http://www.clinicaltrials.gov/ct2/show/NCT01119105 (accessed on 13 April 2013).

Nabriva Therapeutics AG. Study comparing the safety and efficacy of two doses of BC-3781 vs. vancomycin in patients with acute bacterial skin and skin structure infection (ABSSSI). Available online: http://www.clinicaltrials.gov/ct2/show/NCT01119105 (accessed on 13 April 2013).

124

Novak, R. Are pleuromutilin antibiotics finally fit for human use? Ann. NY Acad. Sci. 2011, 1241, 71–81, doi:10.1111/j.1749-6632.2011.06219.x.

Novak, R. Are pleuromutilin antibiotics finally fit for human use? Ann. NY Acad. Sci. 2011, 1241, 71–81, doi:10.1111/j.1749-6632.2011.06219.x.

| WO2002004414A1* | Jul 9, 2001 | Jan 17, 2002 | Gerd Ascher | Pleuromutilin derivatives having antibacterial activity |

| WO2007000004A1* | Jun 26, 2006 | Jan 4, 2007 | Nabriva Therapeutics Forschung | Pleuromutilin derivatives containing a hydroxyamino- or acyloxyaminocycloalkyl group |

| WO2007014409A1* | Jul 26, 2006 | Feb 8, 2007 | Nabriva Therapeutics Forschung | Pleuromutilin derivatives useful as antibacterials |

| WO2008011089A2 | Jul 19, 2007 | Jan 24, 2008 | Mark B Gagner | Wagering game with special-event eligibility feature based on passive game play |

| WO2008113089A1 | Mar 19, 2008 | Sep 25, 2008 | Nabriva Therapeutics Ag | Pleuromutilin derivatives for the treatment of diseases mediated by microbes |

| US20060276503 * | Aug 30, 2004 | Dec 7, 2006 | Glaxo Group Limited | Novel process salts compositions and use |

| US7556948 * | Aug 7, 2003 | Jul 7, 2009 | Glaxo Group Limited | Method for producing crystallized pleuromutilins |

| US20120315672 * | Nov 10, 2010 | Dec 13, 2012 | Massachusetts Institute Of Technology | Methods for microbial production of terpenoids |

| US20130017608 * | Oct 28, 2010 | Jan 17, 2013 | Glaxo Wellcome House | Methods of increasing yields of pleuromutilins |

| US20130204034 * | Jan 31, 2013 | Aug 8, 2013 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Protoilludene synthase |

| US20130224809 * | Nov 21, 2012 | Aug 29, 2013 | Joerg Bohlmann | Diterpene Synthases And Method For Producing Diterpenoids |

| WO2011051820A2* | Oct 28, 2010 | May 5, 2011 | Glaxo Group Limited | Methods of increasing yields of pleuromutilins |

Share this:

PIOGLITAZONE

Pioglitazone

5-[[4-[2-(5-ethyl-2-pyridinyl)-ethoxy]phenyl] methyl]- 2,4- thiazolidinedione

111025-46-8

5-[[4-[2-(5-Ethyl-2-pyridinyl)ethoxy]phenyl]methyl]-2,4-thiazolidinedione

Additional Names: (±)-5-[p-[2-(ethyl-2-pyridyl)ethoxy]benzyl]-2,4-thiazolidinedione

Manufacturers’ Codes: AD-4833

Molecular Formula: C19H20N2O3S

Molecular Weight: 356.44

Percent Composition: C 64.02%, H 5.66%, N 7.86%, O 13.47%, S 9.00%

Properties: Colorless needles from DMF + water, mp 183-184°.

Melting point: mp 183-184°

Therap-Cat: Antidiabetic.

Pioglitazone (Actos) is a prescription drug of the class thiazolidinedione (TZD) with hypoglycemic (antihyperglycemic, antidiabetic) action to treat diabetes. Actos was the tenth-best selling drug in the U.S. in 2008, with sales exceeding $2.4 billion. While pioglitazone does decrease blood sugar levels, studies on the main cardiovascular outcomes has not yielded statistically significant results. Its cardiovascular safety profile compares favorably with rosiglitazone(Avandia), which was withdrawn after concerns about an increased risk of cardiac events. Pioglitazone has been found to be associated with bladder tumors and has been withdrawn in some countries.

Medical uses

Pioglitazone is used for the treatment of diabetes mellitus type 2 either alone or in combination with a sulfonylurea, metformin, orinsulin. There was, however, no statistically significant difference in the main outcomes studied.

Pioglitazone has also been used to treat non-alcoholic steatohepatitis (fatty liver), but this use is presently considered experimental.

| (RS)-5-(4-[2-(5-ethylpyridin-2-yl)ethoxy]benzyl)thiazolidine-2,4-dione | |

| CLINICAL DATA | |

|---|---|

| TRADE NAMES | Actos |

| AHFS/DRUGS.COM | monograph |

| MEDLINEPLUS | a699016 |

| LICENCE DATA | EMA:Link, US FDA:link |

| PREGNANCY CAT. |

|

| LEGAL STATUS | |

| ROUTES | oral |

| PHARMACOKINETIC DATA | |

| PROTEIN BINDING | >99% |

| METABOLISM | liver (CYP2C8) |

| HALF-LIFE | 3–7 hours |

| EXCRETION | in bile |

| IDENTIFIERS | |

| CAS NUMBER | 111025-46-8 |

| ATC CODE | A10BG03 |

| PUBCHEM | CID 4829 |

| IUPHAR LIGAND | 2694 |

| DRUGBANK | DB01132 |

| CHEMSPIDER | 4663 |

| UNII | X4OV71U42S |

| KEGG | D08378 |

| CHEBI | CHEBI:8228 |

| CHEMBL | CHEMBL595 |

| CHEMICAL DATA | |

| FORMULA | C19H20N2O3S |

| MOL. MASS | 356.44 g/mol |

Derivative Type: Hydrochloride

CAS Registry Number: 112529-15-4

Manufacturers’ Codes: U-72107A

Trademarks: Actos (Takeda)

Molecular Formula: C19H20N2O3S.HCl

Molecular Weight: 392.90

Percent Composition: C 58.08%, H 5.39%, N 7.13%, O 12.22%, S 8.16%, Cl 9.02%

Properties: Colorless prisms from ethanol, mp 193-194°. Sol in DMF; slightly sol in ethanol; very slightly sol in acetone, acetonitrile. Practically insol in water; insol in ether.

Melting point: mp 193-194°

nda 021073, actos, 15-7-99, tablet, takeda usa,

ACTOSView pdf

| US PATENT NO | EXPIRY DATE | PATENT USE CODE |

|---|---|---|

| 5965584 | Jun 19, 2016 | U-753 |

| 6150383 | Jun 19, 2016 | U-418 |

| 6150384 | Jun 19, 2016 | U-419 |

| 6166042 | Jun 19, 2016 | U-414 |

| 6166043 | Jun 19, 2016 | U-415 |

| 6172090 | Jun 19, 2016 | U-416 |

| 6211205 | Jun 19, 2016 | U-410 |

| 6271243 | Jun 19, 2016 | U-411 |

| 6303640 | Aug 9, 2016 | U-425 |

| 6329404 | Jun 19, 2016 | U-753 |

Synthesis

………………………….

Many thiazolidinedione derivatives or “glitazones” are known to exhibit hypoglycemic activity and/or blood lipid lowering activity and have been proposed for use in treating, inter alia, diabetes. Some of the more well known and/or studied glitazones include pioglitazone, troglitazone, and rosiglitazone. Pioglitazone, chemically 5-[[4-[2-(5-ethyl-2-pyridinyl)-ethoxy]phenyl] methyl]- 2,4- thiazolidinedione of formula

(1)

is a commercially approved antidiabetic agent. Pharmaceutical compositions comprising pioglitazone, as the hydrochloride salt, are marketed under the brand name ACTOS® (Takeda Chemical Ind.) for treatment of type II diabetes.

Pioglitazone and its hydrochloride have been disclosed in EP 193256 and corresponding U.S. Patent No. 4,687,777. In these patents, the glitazone, such as pioglitazone, can be formed by cyclizing an alpha-bromo acid ester (2) with thiourea. The resulting imino-thiazolidinone (3) is then hydrolyzed to make the corresponding glitazone. For pioglitazone, the reaction can be represented as follows:

The starting alpha-bromo acid ester (2) is taught to be prepared by Meerwein arylation. This process comprises preparing the corresponding aniline (4), diazotation thereof in the presence of hydrobromic acid, and coupling of the product of diazotation with an acrylic acid ester (5) under catalysis by cuprous oxide as shown below:

reduction

(4) (5)

However, forming the alpha-bromo acid ester by the Meerwein arylation reaction can be problematic. The sequence of reactions within this transformation must be controlled precisely. Otherwise the diazo-compound generated during the reaction would react with another nucleophile such as the bromide anion leading to a complicated outcome. Therefore, the reaction often gives a complicated result and lower chemical yield. Furthermore, the preparation of the starting aniline derivative (4) comprises a hydrogenation step that requires a special apparatus, which gives some difficulties when scaling-up.

EP 0 008 203, which is related to U.S. Patent Nos. 4,287,200 and 4,481,141, discloses additional glitazones, i.e., not pioglitazone, that can be formed by several possible methods. In addition to the general scheme described in EP 193256, two more synthetic routes are proposed. One technique comprises a cyclization reaction as shown below to form the intended glitazone:

However, the formation of the starting thiocyano compound is not described. The other technique mentioned in EP 0 008 203 involves coupling the thiazolidine-containing moiety and the substituted alkyl moiety via alkylation of a phenolic oxygen to form the glitazone. If applied to pioglitazone, the reaction would be represented as follows:

(9) (10)

Example 11

Pioglitazone (from 2-thiocyanato-3- {4-[2-(5-ethyl-pyridin-2-yl)-ethoxy]- phenyl} -propionic acid). 0.50 g of 2-thiocyanato-3-{4-[2-(5-ethyl-pyridin-2-yl)-ethoxy]-phenyl}- propionic acid was dissolved in 10 mL of methanesulfonic acid, and the resulting brown solution was stirred overnight. Then, the reaction mixture was poured onto crushed ice upon stirring and sodium hydrogencarbonate was added in portions to neutralize the mixture. Precipitated light brown crystals were filtered off and dried to give 0.70 g of raw product, which was further purified by mixing with 12 % ethanolic solution of hydrogen chloride. The undissolved portion was filtered off, and the filtrate was precipitated with sodium bicarbonate, which gave crystals of pioglitazone

with a m.ρ. of 180 – 184°C.

………………………………..

EP 0193256; ES 8705886; JP 1986267580; US 4687777

The condensation of 2-(5-ethyl-2-pyridyl)ethanol (I) with 4-fluoronitrobenzene (II) by means of NaH in DMF gives 4-[2-(5-ethyl-2-pyridyl)ethoxy]nitrobenzene (III), which is reduced with H2 over Pd/C in methanol to yield the corresponding aniline (IV). The reaction of (IV) with NaNO2/HBr and methyl acrylate (V) in acetone/methanol affords the 2-bromopropionate derivative (VI), which is cyclized with thiourea (VII) by means of NaOAc in refluxing ethanol to provide the 2-imino-4-thiazolidinone (VIII). Finally, this compound is hydrolyzed with refluxing 2N HCl.

……………………………..

EP 0506273

This compound has been obtained by several different methods. The reaction of 2-(5-ethyl-2-pyridyl)ethanol (I) with Ts-Cl and NaOH in THF gives the corresponding tosylate (II), which is condensed with 4-hydroxybenzaldehyde (IV) by means of BnNBu3Cl and NaOH or K2CO3 to yield the aryl ether (V) (1-3). The condensation of (V) with thiazolidine-2,4-dione (VI) in refluxing ethanol affords the 5-benzylidenethiazolidinedione (VII), which is finally reduced with H2 over Pd/C in DMF or dioxane. The reaction of 2-(5-ethyl-2-pyridyl)ethanol (I) with Ms-Cl and TEA in dichloromethane THF gives the corresponding mesylate (III), which is condensed with 4-hydroxybenzaldehyde (IV) by means of K2CO3 to yield the already reported aryl ether (V). The condensation of 2-(5-ethyl-2-pyridyl)ethanol (I) with 4-fluorobenzonitrile (VIII) by means of NaH gives 4-[2-(5-ethyl-2-pyridyl)ethoxy]benzonitrile (IX), which is reduced with RaNi and HCOOH to yield the already reported 4-ethoxybenzaldehyde derivative (V).

………………………….

11th Symp Med Chem (Dec 4-5, Tokushima) 1990,Abst P-11

Two new related syntheses of pioglitazone hydrochloride have been described: 1) The condensation of 2-(5-ethylpyridin-2-yl)ethanol (I) with 4-hydroxybenzaldehyde (II) by means of benzyltributylammonium chloride, NaOH and tosyl chloride gives 4-[2-(5-ethylpyridin-2-yl)ethoxy]benzaldehyde (III), which is condensed with thiazolidine-2,4-dione (IV) in basic medium to afford 5-[-4-[2-(5-ethylpyridin-2-yl)ethoxy]benzylidene]thiazolidine-2,4-dione (V). Finally, this compound is hydrogenated in the usual way. 2) The condensation of alcohol (I) with 4-fluorobenzonitrile (VI) by means of NaH gives 4-[2-(5-ethylpyridin-2-yl)ethoxy]benzonitrile (VII), which is reduced with Raney Nickel and formic acid to the aldehyde (III), already obtained.

…………………..

Beilstein J. Org. Chem. 2013, 9, 2265–2319.

Pioglitazone is clearly related to rosiglitazone (1.40) with its structure only differing in the substitution pattern of the parent pyridine ring. Its synthesis begins with the hydroxymethylation of 2-methyl-5-ethylpyridine (1.11), a commodity chemical obtained from the condensation of acetaldehyde with ammonium acetate (Scheme 12) [43].

At elevated temperatures and pressures 2-methyl-5-ethylpyridine undergoes a condensation reaction with formaldehyde allowing isolation of the chain extended hydroxyethylpyridine 1.70upon distillation although in poor yield [44].

Following subsequent SNAr reaction aryl ether 1.71 is obtained, which is used as crude material in the subsequent Knoevenagel condensation with thiazolidinedione 1.68. In order to reduce the intermediate benzylidene double bond in this example sodium borohydride is used in the presence of cobalt chloride efficiently delivering pioglitazone in high purity.

Scheme 12: Synthesis of pioglitazone.

Other syntheses of pioglitazone use related pyridine building blocks and aim to generate late stage intermediates that deliver the target compound upon de novo synthesis of the thiazolidinedione ring system. For instance phenyl ether1.73 can be obtained via Williamson ether synthesis between mesylate 1.74and phenol 1.75 (Scheme 13).

Removal of the acetyl protecting group under acidic conditions renders aniline1.76 which is subsequently subjected to a Meerwein arylation reaction which occurs via diazotisation and subsequent treatment with acrylonitrile in the presence of cuprous oxide [45-48].

Scheme 13: Meerwein arylation reaction towards pioglitazone.

Alternatively, an equivalent acid functional material can be prepared starting from tyrosine (1.78) via a dual protection of the amino acid unit as the methyl ester and the amine as the benzaldehyde imine (Scheme 14). This is then followed by analogous ether formation with the previously generated mesylate1.74.

Intermediate 1.80 is then hydrolysed to reveal once again the amino acid functionality, which upon diazotisation in the presence of hydrobromic acid selectively forms the α-bromo ester 1.82.

Scheme 14: Route towards pioglitazone utilising tyrosine.

A more direct SNAr approach utilising 4-fluorobenzonitrile as the acceptor and the sodium alkoxide of hydroxyethylpyridine 1.84 as the nucleophile has been successfully conducted (Scheme 15) [49].

The nitrile unit is partially reduced and hydrolysed to the benzaldehyde 1.71using Raney-Ni under transfer hydrogenation conditions in wet formic acid. A Darzens reaction between this aldehyde and ethyl chloroacetate in the presence of sodium ethoxide delivers epoxide 1.87.

The material is next subjected to hydrogenolysis using Pd/C in methanol with a 1 bar hydrogen pressure to reductively ring open the epoxide. Finally, the transformation of the alcohol to the mesylate 1.88 occurs under standard conditions.

Scheme 15: Route towards pioglitazone via Darzens ester formation.

In order to complete the syntheses of pioglitazone as outlined in the previous schemes several procedures for the installation of the thiazolidinedione ring system have been reported [50]. For instance the α-bromoester of intermediate1.82 will render the desired heterocycle upon treatment with sodium isothiocyanate (Scheme 16, A).

Alternatively, the α-amino acid portion of 1.81 can be diazotised under standard conditions and will subsequently deliver the same product when treated with lithium isothiocyanate (Scheme 16, B).

Finally, α-bromonitrile 1.77 can be condensed with thiourea to give pioglitazone after aqueous work-up (Scheme 16, C).

Scheme 16: Syntheses of the thiazolidinedione moiety.

ref for above

43 Frank, R. L.; Pilgrim, F. J.; Riener, E. F. Org. Synth. 1950, 30.doi:10.1002/0471264180.os030.15

44 McGall, G. H.; Barone, A. D. Nucleic Acid Labeling Compounds. U.S. Patent 2001/0018514 A1, Aug 30, 2001.

45 Finch, H.; Fox, C.; Sajad, A. Respiratory Disease Treatment. W.O. Patent WO2010015818, Feb 11, 2010.

46 Adiyaman, M.; Guner, D.; Ridvanoglu, N.; Yurdakul, A. A. Process for the Production of substituted Phenyl Ethers. W.O. Patent WO2004000810, Dec 31, 2003.

47 Nersesian, D. L.; Black, L. A.; Miller, T. R.; Vortherms, T. A.; Esbenshade, T. A.; Hancock, A. A.; Cowart, M. D.Bioorg. Med. Chem. Lett.2008, 18, 355–359. doi:10.1016/j.bmcl.2007.10.067

48 Halama, A.; Hejtmankova, L.; Lustig, P.; Richter, J.; Srsnova, L.; Jirman, J. Method for obtaining Pioglitazone as an antidiabetic agent. W.O. Patent WO02088120, Nov 7, 2002.

48 Halama, A.; Hejtmankova, L.; Lustig, P.; Richter, J.; Srsnova, L.; Jirman, J. Method for obtaining Pioglitazone as an antidiabetic agent. W.O. Patent WO02088120, Nov 7, 2002.

49 Thijs, L.; Zhu, J. Processes for making Pioglitazone and compounds of the processes. W.O. Patent WO2005080387, Sept 1, 2005.

50 Bhanja, C.; Jena, S. J. Chem. Pharm. Res. 2012, 4, 4323–4333.

………………………………..

Pioglitazone of Formula I, chemically (±)-5-[[4-[2-(5-ethyl-2- pyridinyl)ethoxy]phenyl]methyl]-2,4-thiazolidinedione, is used as an adjunct to diet and exercise to improve glycemic control in patients with type 2 diabetes (non-insulin- dependent diabetes mellitus or “NIDDM”).

The commercially available form of pioglitazone is its monohydrochloride salt.

Dehydropioglitazone (hereinafter referred to as “DHP” or “DHP of Formula II”) is known as an intermediate in the synthesis of pioglitazone or salts thereof.

In addition, DHP is also present as a process impurity or degradation product in pioglitazone or salts thereof. Several reasons are attributed for the generation of DHP in pioglitazone. Some factors linked to the generation of this impurity include the incomplete reduction of DHP and the oxidation of pioglitazone during isolation or while on stability.

Several processes are known in the literature for making pioglitazone or a salt thereof, for example, U.S. Patent Nos. 4,687,777; 5,585,495; 4,812,570; 5,554,758; 5,952,509; and 6,100,403; U.S. Publications 2002/0106762 and 2002/0050563; WO 03/53367; WO 03/80056; WO 2004/07490; WO 2004/024059; WO 2004/101560; WO 2004/101561 , WO 2005/049610; WO 2008/075380; WO 2006/1 17654; WO

2008/142706; WO 2005/058827; WO 2009/104200; and WO 2009/133576.

U.S. Publication 2006/0252803 provides a process for the preparation of pioglitazone which involves dissolving DHP of Formula II in formic acid and hydrogenating with hydrogen in the presence of 10% Palladium on Carbon under 2 atmospheric pressures and a temperature of 80°C. This process reportedly provides pioglitazone having less than about 0.14 % of the impurity at RRT 0.64 (HPLC).

It also provides a process for the preparation of pioglitazone which involves combining DHP of Formula II with dimethylformamide and hydrogenating with hydrogen in the presence of Palladium on Carbon under 3 atmospheric pressures and a temperature of 50°C. It is reported that -68.5% of DHP was converted to pioglitazone, containing about 3.5 % impurities (HPLC).

U.S. Publication 2009/118514 provides various purification methods for pioglitazone. It provides obtaining a solution of pioglitazone with a mixture of dimethylformamide (DMF) and 4% water, DMF and 5% methanol, DMF and 10% methanol, 1 ,4-dioxane or DMF and isopropyl alcohol at a temperature of about 90°C and precipitating pioglitazone from the solution by cooling to a temperature of about 25°C.

U.S. Publication 2007/0078170 provides a process for the preparation of pioglitazone which involves obtaining a clear solution of pioglitazone in

dimethylformamide at 85°C and adding methanol at a temperature of 60°C and further cooling to 10°C to precipitate pioglitazone.

Impurities in pioglitazone or its hydrochloride salt, or any active pharmaceutical ingredient (“API”), are undesirable and, in extreme cases, might even be harmful to a patient being treated with a dosage form containing the API. The purity of an API is critical for commercialization. The product of a chemical reaction is rarely just the target compound. Side products and by-products of the reaction and adjunct reagents used in the reaction will, in most cases, also be present in the product in varying amounts. Extra effort is often required to get pharmaceutically acceptable levels of purity of the target compound.

EXAMPLES

Example 1 : Purification of Pioglitazone

Dimethylformamide (10 mL) was heated to 80°C to 82°C and pioglitazone (2 g) was added to the hot solution and stirred at 80°C to get a clear solution. The solution was cooled to 75 °C and mixture of acetone (10 mL) and methanol (10 mL) was added to the solution in 30 to 45 minutes at 70°C to 75°C. After complete addition, the reaction mass was cooled to 30°C to 35°C slowly in about 2 hours and was filtered. The solid was washed with dimethylformamide/acetone/methanol mixture (6 mL).

DHP impurity content after purification: 0.05%

DHP impurity content before purification: 0.16%

Yield: 90% Example 2: Purification of Pioglitazone

Dimethylformamide (200 mL) was heated to 80°C to 85 °C and pioglitazone (40 g) was added to the hot solution and stirred at 80°C to get a clear solution. The solution was cooled to 75°C and mixture of acetone (200 mL) and methanol (200 mL) was added to this solution in 30 minutes to 45 minutes at 65°C to 75°C. After complete addition, the reaction mass was cooled to 30°C to 35°C slowly in about 2 hours and was filtered. The solid was washed with acetone/methanol mixture (100 mL).

DHP impurity content after purification: 0.04%

DHP impurity content before purification: 0.15%

Yield: 92%

Example 3: Purification of Pioglitazone (Control)

Dimethylformamide (25 mL) was heated to 80°C to 85 °C and pioglitazone (5 g) was added at 85°C. The solution was cooled to 55°C and a mixture of acetone (25 mL) and methanol (25 mL) was added to the solution in 30 minutes to 45 minutes at 55°C to 60°C. After complete addition, the reaction mass was cooled to 35°C to 37°C slowly in about 2 hours and was filtered. The solid was washed with acetone/methanol mixture (10+lOmL).

DHP impurity content after purification: 0.11%

DHP impurity content before purification: 0.12%

Yield: 92%

………………………………………

EXAMPLE 5

Conversion of Pioglitazone to Pioglitazone Hydrochloride

Pioglitazone hydrochloride was prepared in a similar manner as exemplified in Example 4. To de-ionized water (7 L) heated to 80° C. added the product obtained from Example 4 (1 Kg) under stirring at 80° C. It was further stirred for 10 min at 80 – 82° C. and conc. HCI (0.5 L) was added to it under stirring at 80° C. The resultant mass was further stirred for 10 min at 80-82° C. to obtain a clear solution. The solution was filtered through celite bed directly into RB flask and the bed was washed with IN HCI (1 L) at 80-82° C. It was cooled to 5° C. under stirring at 5-0° C. for 1 hr. The solids were filtered under N2atmosphere and dried on the Büchner funnel for about 15 minutes. The product obtained was then dried under vacuum at 55-60° C. to afford the title compound.

Yield: 930.0 g (93%)

HPLC Purity: 99.61%

Samples of pioglitazone hydrochloride prepared in examples 4 and 5 were studied for their solubility, as set forth below:

………………………

Literature References:

Insulin sensitizer. Prepn: K. Meguro, T. Fujita, EP 193256; eidem, US 4687777(1986, 1987 both to Takeda);

T. Sohda et al., Arzneim.-Forsch. 40, 37 (1990).

Pharmacology: H. Ikeda et al., ibid. 156. HPLC determn in serum: W. Z. Zhong, D. B. Lakings, J. Chromatogr. 490, 377 (1989).

Mechanism of action: C. Hofmann et al., Endocrinology 129, 1915 (1991); M. Kobayashi et al., Diabetes 41, 476 (1992).

Effect on adipocyte differentiation: T. Sandouk et al., Am. J. Physiol. 264,C1600 (1993).

Clinical evaluation in noninsulin-dependent diabetes: R. Kawamori et al.,Diabetes Res. Clin. Pract. 41, 35 (1998).

| US8067450 | Sep 15, 2008 | Nov 29, 2011 | Metabolic Solutions Development Company | Thiazolidinedione analogues for the treatment of metabolic diseases |

| US8304441 | Nov 16, 2011 | Nov 6, 2012 | Metabolic Solutions Development Company, Llc | Thiazolidinedione analogues for the treatment of metabolic diseases |

| WO2011017244A1* | Aug 2, 2010 | Feb 10, 2011 | Metabolic Solutions Development Company | Polymorphs of 5-(4-(2-(5-ethylpyridin-2-yl)-2-oxoethoxy)benzyl)-1,3-thiazolidine-2,4-dione (mitoglitazone) |

| WO2012153312A1 | May 11, 2012 | Nov 15, 2012 | Ranbaxy Laboratories Limited | Process for the purification of pioglitazone |

| WO2003053367A2 | Dec 20, 2002 | Jul 3, 2003 | Ben-Zion Dolitzky | Hydrogenation of precursors to thiazolidinedione antihyperglycemics |

| WO2003080056A2 | Mar 21, 2003 | Oct 2, 2003 | Ben-Zion Dolitzky | Fine particle size pioglitazone |

| WO2004007490A2 | Jul 15, 2003 | Jan 22, 2004 | Cadila Healthcare Ltd | A process to prepare pioglitazone via several intermediates. |

| WO2004024059A2 | Aug 29, 2003 | Mar 25, 2004 | Parag Narayan Gadkari | Improved process for preparation of thiazolidinedione derivatives |

| WO2004101560A1 | May 11, 2004 | Nov 25, 2004 | Frantisek Picha | Processes for making thiazolidinedione derivatives and compounds thereof |

| WO2004101561A1 | May 13, 2004 | Nov 25, 2004 | Frantisek Picha | Pioglitazone salts, such as pioglitazone sulfate, and pharmaceutical compositions and processes using the same |

| WO2005049610A1 | Oct 27, 2004 | Jun 2, 2005 | Sudhir Nambiar | Process for preparing thiazolidinediones |

| WO2005058827A1 | Dec 16, 2004 | Jun 30, 2005 | Janos Fischer | Process for the synthesis of pioglitazone hydrogen chloride |

| WO2006117654A1 | May 3, 2006 | Nov 9, 2006 | Ranbaxy Lab Ltd | Processes for the preparation of pioglitazone or salts thereof |

| WO2008075380A2 | Dec 20, 2007 | Jun 26, 2008 | Ind Swift Lab Ltd | Process for the preparation of thiazolidine derivatives |

| WO2008142706A2 | May 19, 2008 | Nov 27, 2008 | Yogendra Kumar Chauhan | Novel process for the synthesis of pioglitazone and its salts thereof |

| WO2009104200A1 | Apr 8, 2008 | Aug 27, 2009 | Biocon Limited | A method for preparation of thiazolidinedione derivatives |

| WO2009133576A1 | Apr 28, 2008 | Nov 5, 2009 | Erregierre S.P.A. | A process for the preparation of 4-[2-(5-ethyl-2-pyridyl)ethoxy]nitrobenzene and pioglitazone |

| US4687777 | Jan 17, 1986 | Aug 18, 1987 | Takeda Chemical Industries, Ltd. | Thiazolidinedione derivatives, useful as antidiabetic agents |

| US4812570 | Jul 14, 1987 | Mar 14, 1989 | Takeda Chemical Industries, Ltd. | Method for producing thiazolidinedione derivatives |

| US5554758 | Jun 7, 1995 | Sep 10, 1996 | Takeda Chemical Industries, Ltd. | P-/2-/5-ethyl-2-pyridyl/ethoxy/benzaldehyde |

| US5585495 | Dec 4, 1992 | Dec 17, 1996 | The Upjohn Company | Using a cobalt compound, ligand and reducing agent |

| US5952509 | Jun 23, 1997 | Sep 14, 1999 | Takeda Chemical Industries, Ltd. | Reacting p-hydroxybenzaldehyde with a pyridyl-ethyl sulfonate derivative to form 4-(2-(substituted or nonsubstituted-2-pyridyl)ethoxy) benzaldehyde |

| US6100403 | Apr 12, 1999 | Aug 8, 2000 | Takeda Chemical Industries, Ltd. | Production of benzaldehyde compounds |

| US20020050563 | Sep 14, 2001 | May 2, 2002 | Smithkline Beecham P.L.C. | Process for the preparation of pharmaceutically active thiazolidine or oxazolidine compounds by a yeast reductase |

| US20020106762 | Oct 9, 2001 | Aug 8, 2002 | Smith Kline Beecham Plc | Generating preerential compound for use as prophylactic agent; obtain chemical intermediate, incubate with enzyme, recover prophylactic agent |

| US20060252803 | Jan 26, 2006 | Nov 9, 2006 | Ben-Zion Dolitzky | Hydrogenation of precursors to thiazolidinedione antihyperglycemics |

| US20070078170 | Aug 30, 2004 | Apr 5, 2007 | Khanduri Chandra H | Process for the preparation of pioglitazone |

| US20090118514 | Nov 5, 2008 | May 7, 2009 | Raghupathi Reddy Anumula | Processes for preparing pioglitazone and its pharmaceutically acceptable salts |

| WO2012153312A1 | May 11, 2012 | Nov 15, 2012 | Ranbaxy Laboratories Limited | Process for the purification of pioglitazone |

| EP1734036A1 * | Jun 14, 2005 | Dec 20, 2006 | Well-being Biochemical Corp. | Process for preparation of tamsulosin and its derivatives |

| WO1997031907A1* | Feb 26, 1997 | Sep 4, 1997 | Grady Evan Boswell | Substituted 4-hydroxy-phenylalcanoic acid derivatives with agonist activity to ppar-gamma |

| WO2002088120A1* | Apr 25, 2002 | Jul 11, 2002 | Ales Halama | Method for obtaining pioglitazone as an antidiabetic agent |

| EP0008203A1 * | Aug 3, 1979 | Feb 20, 1980 | Takeda Chemical Industries, Ltd. | Thiazolidine derivatives, preparing same and pharmaceutical compositions comprising same |

| EP0193256A1 * | Jan 15, 1986 | Sep 3, 1986 | Takeda Chemical Industries, Ltd. | Thiazolidinedione derivatives, their production and use |

Keywords: Antidiabetic; Thiazolidinediones; Insulin Sensitizer.